![]()

Whatever the size, model or application of your engine, there's a Racor fuel

filter/water separator that will make it run cleaner, smoother and longer. And

while all Racor filter/separators share advanced technology and water-repelling

Aquabloc media, there are important differences in features and configurations.

Take time to carefully review the specifications so that you can be sure of

maximum efficiency and optimum protection from your Racor filtration system.

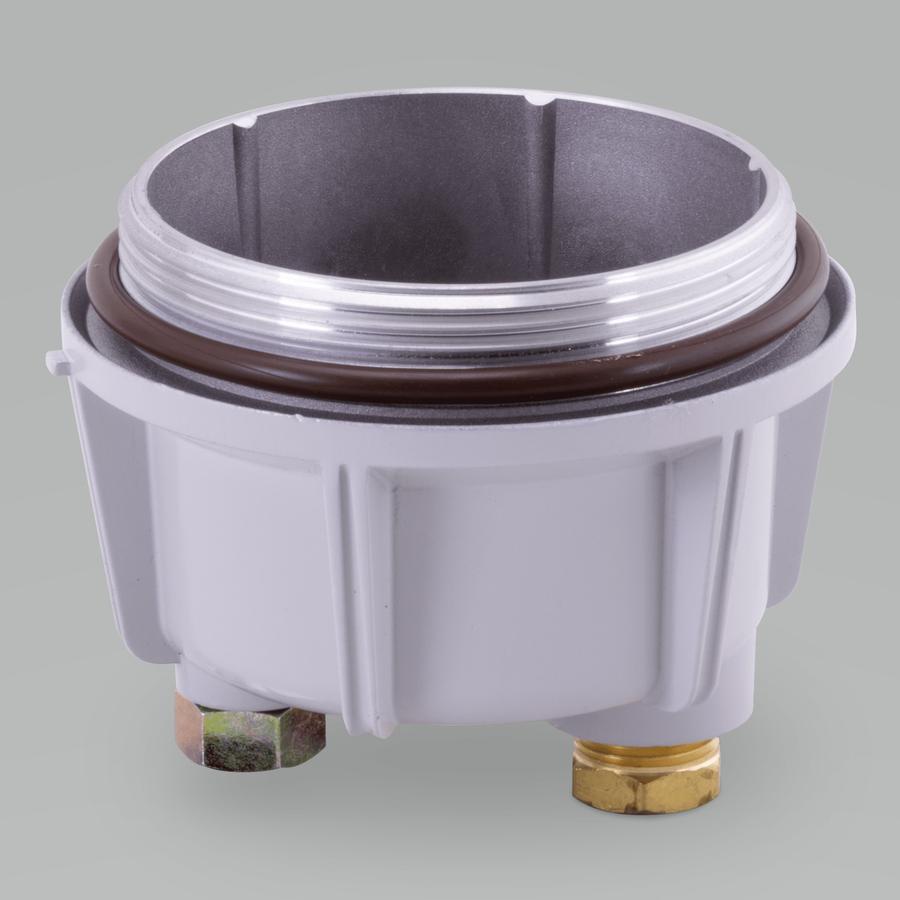

Lightweight Heavyweights

Easy to install, and even easier to service, there are specific assembly, filter

element and option packages to match every application.

- Install a compact spin-on filter/separator with an integral heater to maximize equipment uptime in cold weather operations.

- Spin a filter/separator with a see-thru bowl and replaceable Aquabloc element directly on to an existing engine filter head.

- Most models feature heads with multiple ports, so installation is quick and easy.

- There are metal bowls for gasoline or severe operating conditions.

- There's a choice of thermostatically-controlled heaters - coolant, electric resistance and PTC - to prevent fuel gelling and waxing. Some models allow for a combination of heaters to assist starting and keep engines running in cold climates.

| There are important differences among Spin-On Series features which affect performance and applications. |

|

|

|

|

|

|

|

||||||||||||||

| Model # | 110A | 120RMAM | 230RMAM | 245RMAM | 460MAM | 490MAM | 4120MAM | ||||||||||||||

| Maximum Flow Rate | 15 gph / 57 lph Diesel 35 gph / 133 lph Gas |

15 gph / 57 lph |

30 gph / 114 lph |

45 gph / 170 lph |

60 gph / 227 lph |

90 gph / 341 lph |

120 gph / 454 lph |

||||||||||||||

| Gasoline or Diesel (1) | Both | Diesel | Diesel | Diesel | Diesel | Diesel | Diesel | ||||||||||||||

| Vacuum Installation | Yes | Yes | Yes | Yes | Yes | Yes | Yes | ||||||||||||||

| Pressure Installation | Yes | Yes | Yes | Yes | Yes | Yes | Yes | ||||||||||||||

| Maximum PSI (2) | 150 psi | 7 psi | 30 psi | 30 psi | 30 psi | 30 psi | 15 psi | ||||||||||||||

| Clean Pressure Drop PSI / kPa | 0.15 psi 1.08 kPa |

0.15 psi 1.08 kPa |

0.31 psi 2.14 kPa |

0.61 psi 4.21 kPa |

0.39 psi / 2.7 kPa |

0.05 psi / 6.5 kPa |

1.4 psi / 9.7 kPa |

||||||||||||||

| No. of Ports | 4 | 4 | 3 | 3 | 4 | 4 | 4 | ||||||||||||||

| Port Size | 1/4” NPT | 1/4” NPT | 1/4” NPT | 1/4” NPT | 3/8” NPT | 3/8” NPT | 3/4” SAE | ||||||||||||||

| Integral Primer Pump (3) | No | 122R | Yes | Yes | Yes | Yes | Yes | ||||||||||||||

| Replacement Element No. (4) | R11 | R12 | R20 | R25 | R60 | R90 | R120 | ||||||||||||||

| Bowl / See-Thru | No | Yes | Yes | Yes | Yes | Yes | Yes | ||||||||||||||

| Bowl / Metal (1) | STD | 122 M | 230RMAM | 245RMAM | 460MAM | 490MAM | 4120MAM | ||||||||||||||

| Drain Type | Positive Seal | Positive Seal | Positive Seal | Positive Seal | Positive Seal | Positive Seal | Self-Vent | ||||||||||||||

| Water Sensor Option | Yes | Yes | Yes | Yes | Yes | Yes | Yes | ||||||||||||||

| Height | 6” / 152 mm | 5.7” / 145 mm | 9” / 229 mm | 10.5” / 267 mm | 11” / 279 mm | 11.8” / 300 mm | 15” / 381 mm | ||||||||||||||

| Width | 3.2” / 81 mm | 3.2” / 81 mm | 4” / 102 mm | 4” / 102 mm | 4.5” / 114 mm | 4.5” / 114 mm | 4.5” / 114 mm | ||||||||||||||

| Depth | 3.2” / 81 mm | 3.2” / 81 mm | 4” / 102 mm | 4” / 102 mm | 4.8” / 121 mm | 4.8” / 121 mm | 4.8” / 121 mm | ||||||||||||||

| Weight | 1.3 lbs / 0.59 Kg | 1.3 lbs / 0.59 Kg | 2 lbs / 0.90 Kg | 2.2 lbs / 1.0 Kg | 2.7 lbs / 1.3 Kg | 2.9 lbs / 1.4 Kg | 3.9 lbs / 1.8 Kg | ||||||||||||||

| Special Notes: 1. Above units feature metal bowls and are approved for diesel service and are UL Listed, USCG Accepted. 2. Model 110A may be used in pressure applications (up to 100 PSI) and gasoline service. UL Listed. 3. The 200RMAM and 400MAM Series units include the head mounted hand priming pump as standard. 4. The 4120MAM model features large 3/4”UNF ports for high-flow, low-restriction applications. 5. Allow at least 2 inches (51 mm) clearance under the units for element replacement and water collection. |

|||||||||||||||||||||