Unless specified (or sold in spools), line is sold by the foot.

What rope should I buy? A breakdown of the various types:

- Anchoring: Normally anchor rode (the rope between your boat and anchor) is made from stretchy 3-strand or braided nylon. This will absorb a huge amount of shock that otherwise would expose your boat's hardware to damage.

- Bungee cord: Our bungee cord comes with a rubber core and nylon sheath. Do not use bungee cord in any load bearing applications, but can be very useful for tie-downs or similar purposes

- Dinghy Braid: Low cost, simple polyester line with a diamond pattern on the jacket. This pattern provides a little extra friction when pulling small diameter lines by hand; useful for dinghies and small boats without winches.

- Dock & Mooring Lines: These lines are usually made from stretchy nylon, there are polyester options available with shock absorbers built in - or snubbers can be used. Available in several colours. While nylon has more elasticity, polyester provides excellent durability and strength. Mooring lines should have stainless steel eyelets installed on the ends.

- Fender Lines: Usually made from nylon, but often available in polyester, strength isn't an issue, but look for nice, comfortable, large diameters in dynamic colours.

- Hi-Brite Spools: These spools are sold in bulk lengths, usually 100 feet or more, in various materials, but normally high strength polyester or hi-tech Spectra cores. These spools are small diameters, ideal for racing dinghy applications.

- High-Tech Rope: High-tech ropes are designated as such because their core strength is significantly higher than the strength of polyester. Spectra and Dyneema are essentially the same product; Ultra high molecular weight polyethylene, with different brand names. They offer strength-to-weight ratios similar to steel. Of course, they cost more, but in many applications, such as replacing wire halyards or lifelines, the savins in weight and simplicity is highly worth it.

- Lightweight Floating Rope: When rope floats, it is because it has not absorbed water. Therefore, these ropes are 100% synthetic and lightweight. Ideal for towing lines, heaving line, or other applications which require flotation. However, the strength of these ropes are not as high as polyester (usually having a polypropylene core), and often as suspectible to sun damage. Technological advancements are allowing these ropes to become stronger and more durable, but currently they are intended for floating applications only.

- Manila Rope: Unless you're sailing a turn-of-the-century barque, you should not choose manila rope for any application other than strictly decorative. However, manila rope can provide stunning nautical effects!

- Polyester Yacht Braid: This type of line will meet most of your needs! Excellent durability and strength, moderate cost (marginally more than nylon) with low stretch and available in various colours. When in doubt, go with polyester.

- Wire to Rope Halyards: These lines have a portion of stainless

steel wire, spliced directly to polyester rope. This line is meant to replace

existing wire-to-rope halyards. Do not install a wire-rope halyard on a boat

that currently has an all-rope halyard - the wire will destroy the sheaves

intended for rope!

Metric-Imperial

Conversion Chart (these are rounded to their closest companions!) |

|||||||

1mm |

2mm |

2.5mm |

3mm |

4mm |

5mm |

6mm |

8mm |

3/64" |

5/64" |

7/64" |

1/8" |

5/32" |

3/16" |

1/4" |

5/16" |

9.5mm |

11mm |

12.5mm |

16mm |

19mm |

22mm |

25mm |

30mm |

3/8" |

7/16" |

1/2" |

5/8" |

3/4" |

7/8" |

1" |

1-1/4" |

PROPER LOADING OF ROPE

The following information may help you decide the right size of line to purchase. It can also be helpful determining the load placed on other hardware on your boat, such as shackles, blocks, padeyes and eye straps.

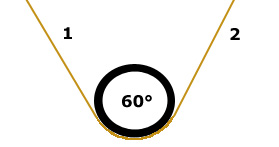

The breaking strength of rope is based on direct pull along a single length of rope. When slings, using two or more legs to carry the load are properly employed, the rope's safe working load is substantially increased. However, as illustrated below, the load factor on each kilogram of the sling is greatly increased as the sling angle becomes smaller.

Therefore the use of slings requires certain precautions as well as a knowledge of safe working loads permissible. For best results, sling angles should never be more than 90-degrees, and rarely less than 45-degrees. Remember to regularly inspect splices and all fittings! Consider using rub strakes if the rope will be in contact with surfaces that may chafe!

HOW TO COMPUTE SAFE WORKING LOADS ON ROPE Use the following equation when rope breaking strength and sling angles are known: Example: To find safe working load for two-leg sling (2:1 purchase) of 3/8" Polyester (breaking strength 4081kg) at an angle of 60-degrees (sine = 0.866)

|

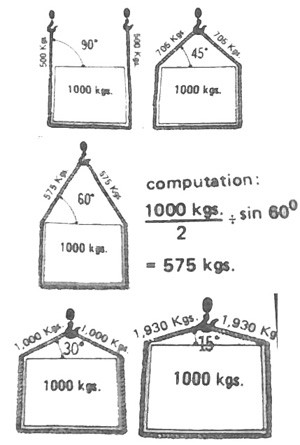

HOW TO COMPUTE THEORETICAL LOAD ON YOUR SYSTEM Use the following equation to determine how much load will be placed on the rope when setting up a purchase system or running your lines through fairleads, blocks or other hardware: Example: Load of 1000 kgs in a two-leg sling (2:1 purchase) running through a sheave at an angle of 60-degrees.

5/16" Polyester or 1/4" Spectra would do the job in this example. Other angles produce different results (see below):

|

Angle-to-Sine Conversion Chart:

You can use a scientific calculator to determine sine. Simply punch in the angle (as a whole number, eg 40) and press the "sine" function (answer 0.642).

| Angle | Cosine | Sine |

| 5 | 0.996 | 0.087 |

| 10 | 0.985 | 0.173 |

| 20 | 0.9397 | 0.342 |

| 30 | 0.866 | 0.500 |

| 40 | 0.766 | 0.642 |

| 50 | 0.6428 | 0.766 |

| 60 | 0.5 | 0.866 |

| 70 | 0.342 | 0.939 |

| 80 | 0.1736 | 0.985 |

| 90 | 0 | 1.000 |

Still need a scientific calculator? If you're running Windows, you probably

have one! Just go to "Start", "All Programs", "Accessories",

then choose "Calculator".

The calculator's default setting is "Standard", so if you don't see

the SIN/COS/TAN functions, click on "View", then "Scientific".