With so many choices, which sealant is right for you? Why not just use silicone?

When you drill a hole through your boat's hull to attach hardware, plumbing fittings or electronic transducer (such as knotmeters), you are effectively breaching the waterproof shell that holds your boat afloat!

Holes are essentially a direct route for water to penetrate your boat's core material (the wood or foam sandwiched between the fibreglass layers of your hull) which can lead to catastrophic water damage. Even above the waterline, it is imperative that you seal every single hole with sealant - no matter how small!

Bonding with Adhesive Sealants

While many people refer to sealants as "silicone", a high performance sealant is rarely silicone-based.. so let's avoid getting them confused! We should state that while silicone still has its place in some places on a boat, it should never be used to bond hardware. Silicone is excellent for forming "gasket-like" seals, but provides very little actual adhesion between two surfaces. In other words, it fills the gap but that's about it.

When in doubt about which type of sealant to use, we recommend polyurethane-based sealants.

One important point to remember is the stronger a sealant is, generally the more difficult it is to remove! We recommend saving time and frustration by considering the Sealant Removers listed on our site.

Curing Sealants Underwater

Don't let your jaw drop; for the most part, adhesive sealants are moisture cured! In other words, they cure better underwater than above! Just double check the label to confirm.

Here's a simple guide to the common and best selling sealants. We have added a silicone sealant at the bottom for comparative purposes!

|

Product

|

Tack Free / Full Cure

|

Characteristics

|

|

UV Resistant Sealants

|

||

| 3M 4000 UV | <2 hrs / 48 hrs |

|

| Sikaflex 295-UV | 60 min / 6-10 days |

|

|

User-friendly Sealants (Easily Removed!)

|

||

| 3M 4200 | 1-2 hrs / 24-48 hrs |

|

| Sikaflex 291 | 45 min / 7-14 days |

|

| Sikaflex 291-LOT | 3-5 hrs / 7-14 days |

|

|

High Performance Sealants

|

||

| 3M 5200 | 48 hrs / 7-14 days |

|

| 3M 5200 Fast Cure | 1-2 hrs / 24-48 hrs |

|

|

Silicone-Polyurethane Hybrids & Polysulfides

|

||

| BoatLife LifeSeal | N/A / N/A |

|

| BoatLife LifeCalk | 1-3 days / N/A |

|

|

Silicone Sealants

|

||

| 3M Silicone Sealant | 20 min / 24-48 hrs |

|

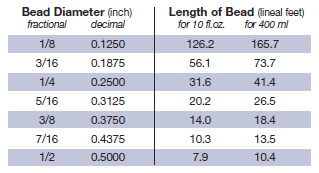

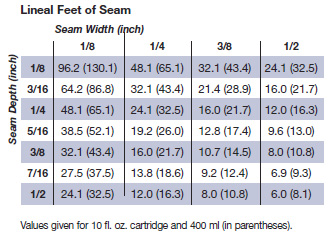

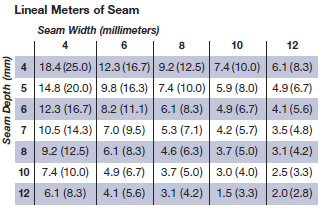

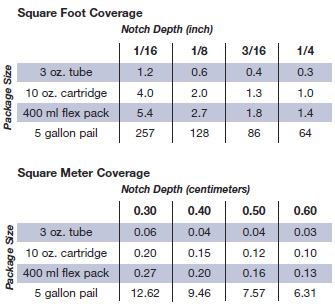

Theoretical Coverage Charts for Adhesive Sealant Products

Given the desired diameter of a bead or the dimensions of a seam, the coverage obtained from a cartridge or flex pack can be looked up in the following charts. Note that the values are calculated for "no waste." The actual coverage will be based on application technique and overfill.

|

|

Area Coverage

Should it be necessary to cover an area with the adhesive sealant, the material should be dispensed from the container and spread with a trowel. Most trowels for spreading adhesives will have a notched edge to facilitate control of the thickness being applied. When the notch depth is known or can be measured the coverage area can be determined from the following tables. Should it be necessary to apply a solid layer of a specific thickness, take the value given in the following table and divide the area by two.

Information provided by 3M.